The Adhesive Tape Manufacturer

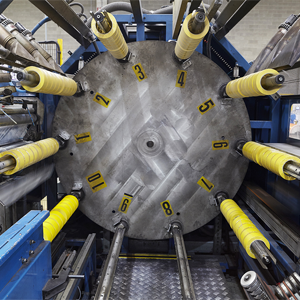

Behind the scenes: PPM Industries’ production core

PPM Industries is a global manufacturer and supplier of adhesive tapes to the worldwide market. On this page, we unveil the secrets that make our adhesive tapes a trusted ally for professional and utility use in a wide range of sectors such as automotive, painting, packaging, building and construction.

Adhesive tape manufacturing: the process, made simple

Each roll of tape is made up of two main components: the backing material and the adhesive layer stick to it. The adhesive tape manufacturing is essentially the process of joining the two in the final product, the tape we all know. How does that work?

- Step 1: the adhesive. We prepare the adhesive for the coating by mixing it with a solvent that helps its transfer onto the backing. The adhesive and the solvent used depend on the kind of tape we want to manufacture: usually, we speak about rubber resins, hot-melt and acrylic adhesives, with acrylic or water-base solvents.

- Step 2: the coating. The backing roll is unwound to be ready for the coating. Again, the backing material depends on the kind of tape we are producing. At this point, the adhesive is transferred onto the backing in a thin, even layer that turns solid as the solvent evaporates

- Step 3: the slitting. Once the adhesive has dried, the backing is rewound so to create the roll. The roll is still a large, wide band that sums up several final products: so, the final step is the slitting of the cylinder and the packaging of the single tape rolls, ready for delivery.

Read here to know more about PPM’s services and why it’s different than other tape manufacturing companies.

Focusing on the product: what we manufacture

We are wide-range self adhesive tape manufacturers, who cover the needs of different markets. Our comprehensive production includes:

- Masking tapes for both the automotive and the painting sector

- Duct tapes for professional and utility use

- Double sided tapes and double sided carpet tapes

- Paper packaging tapes, filament tapes and strapping tapes

Let’s go into detail:

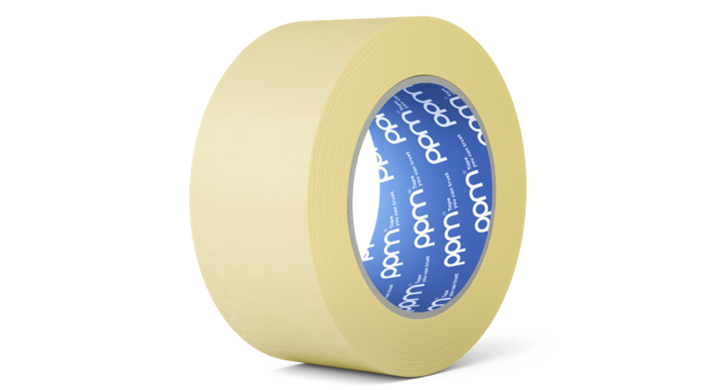

Masking tapes

PPM Industries’ masking tapes are manufactured with different paper backings and a rubber resin or a water-base acrylic adhesive that are easy to remove without leaving residue. The rubber resin adhesives can be both solvent-free or solvent-borne according to the product. The paper backing is easy to tear, light and economic. As mentioned, we manufacture both high-temperature masking tapes for the car refinishing sector and regular masking tapes for the painting sector. Discover more about our masking tapes by browsing the dedicated page, or take a look at our automotive masking tape range!

Duct tapes

Duct tapes are normally manufactured with a PE backing and a layer of solvent-free synthetic rubber resin. The synthetic backing guarantees exceptional tensile strength and elongation properties, making the tape ideal for wrapping and repairing applications on irregular surfaces. At the same time, the material is waterproof. The hot-melt adhesive is powerful enough to stick to different materials in semi-permanent applications. Discover more about PPM Industries’ Duct Tapes!

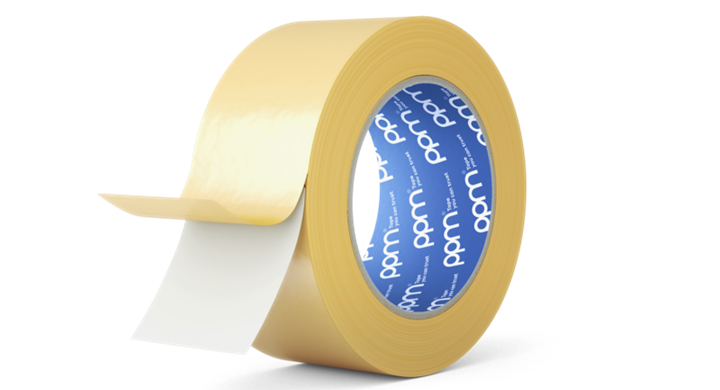

Double sided tapes

Double sided tapes feature a paper siliconized liner with a film or fabric backing that divides the double layer of synthetic rubber resin. The combination of backings and adhesive guarantees clean adhesion and excellent holding both in industrial and DIY applications. The range includes a carpet tape to fasten carpets and mats with no need for glue. Discover more about our range of double sided tapes!

Packaging tapes

Packaging tapes include a range of different products for different applications:

- Paper packaging tapes to seal cardboard boxes

- Filament tapes for heavy-duty packaging and reinforcements

- Strapping tapes for general bundling applications and pallet fastening

Each product family is manufactured with specific backings and adhesives to enhance the qualities required by its application. For example, fiberglass reinforcements in the filament tapes ensure higher tensile strength, while the hot-melt adhesive adds a powerful hold. Here you can find out more about our filament tapes, while here you can discover more about our range of packaging tapes. To know more about our activity as a strapping tape manufacturer, read here.

Industrial tape manufacturers and suppliers

PPM is specifically specialized in manufacturing and supplying industrial tape, for professional use in the industrial sector. Specifically, PPM has a long established experience in manufacturing adhesive tape for the following fields:

- Building & Construction

- Painting & Renovation

- Automotive Aftermarket

- Packaging

According to the area of application, PPM manufactures a different range of adhesive tapes, ideal to answer a complex multitude of different needs. Read here to know more about our activity as industrial tape manufacturers and suppliers

Private label manufacturing

As versatile self adhesive tape manufacturers, PPM Industries also offers a completely customized service as far as tape design and packaging are concerned. We can produce each tape with specified size and colors, your logo and your graphic customizations on the following elements:

- Tape core

- Shrink packaging

- Label

- Roll packaging

- Shipping box

- Shipping label

- Display

PPM really has it all.

If you’re interested in knowing more about why PPM is different the other average adhesive tape companies, contact us! We will gladly tell you more about us and our services.